Chitsulo Chokonzedweratu Chimango Chosungiramo Nyumba Yosungiramo Zinthu Zo ...

kapangidwe ka chitsulo cha mafakitaleNdi nyumba yopangidwa ndi zitsulo ndipo ndi imodzi mwa mitundu yayikulu ya nyumba. Nyumbayi imapangidwa makamaka ndi matabwa achitsulo, mizati yachitsulo, kapangidwe ka chitsulo cha mafakitale ndi zinthu zina zopangidwa ndi chitsulo cha gawo ndi mbale zachitsulo, ndipo imagwiritsa ntchito silanization, manganese phosphating yoyera, kutsuka ndi kuumitsa, galvanizing ndi njira zina zopewera dzimbiri.

*Kutengera ndi ntchito yanu, tikhoza kupanga dongosolo lachitsulo lotsika mtengo komanso lolimba kwambiri kuti likuthandizeni kupanga phindu lalikulu pa ntchito yanu.

| Dzina la malonda: | Kapangidwe ka Chitsulo Chomangira |

| Zofunika: | Q235B, Q345B |

| Chimango chachikulu: | Mtanda wachitsulo wooneka ngati H |

| Purlin: | C,Z - mawonekedwe a chitsulo chopangidwa ndi purlin |

| Denga ndi khoma: | 1. pepala lachitsulo lopangidwa ndi dzimbiri; 2. mapanelo a masangweji a ubweya wa miyala; 3. Ma panelo a masangweji a EPS; 4.magalasi a masangweji a ubweya |

| Chitseko: | 1. Chipata chogubuduzika 2. Chitseko chotsetsereka |

| Zenera: | Chitsulo cha PVC kapena aluminiyamu |

| Pansi pa mtsempha: | Chitoliro chozungulira cha PVC |

| Ntchito: | Mitundu yonse ya malo ogwirira ntchito zamafakitale, nyumba yosungiramo zinthu zakale, nyumba zazitali |

NJIRA YOPANGIRA ZIPANGIZO

UBWINO

Mphamvu zokwanira

Mphamvu imatanthauza kuthekera kwa chitsulo kupirira kuwonongeka (kusweka kapena kusinthika kosatha). Izi zikutanthauza kuti, palibe kulephera kwa kukolola kapena kusweka komwe kumachitika pansi pa katundu, ndipo kuthekera kogwira ntchito mosamala komanso modalirika kumatsimikizika. Mphamvu ndi chinthu chofunikira chomwe ziwalo zonse zonyamula katundu ziyenera kukwaniritsa, kotero ndichonso cholinga chachikulu chophunzirira.

Kuuma kokwanira

Kuuma kumatanthauza kuthekera kwa chiwalo chachitsulo kukana kusintha kwa zinthu. Ngati chiwalo chachitsulocho chasintha kwambiri chikakanikizidwa, sichingagwire ntchito bwino ngakhale chisanawonongeke. Chifukwa chake, chiwalo chachitsulocho chiyenera kukhala ndi kuuma kokwanira, ndiko kuti, palibe kulephera kolimba komwe kungaloledwe. Zofunikira za kuuma ndizosiyana pamitundu yosiyanasiyana ya zigawo, ndipo miyezo ndi zofunikira zoyenera ziyenera kuwonedwa mukamagwiritsa ntchito.

Kukhazikika

Kukhazikika kumatanthauza kuthekera kwa gawo lachitsulo kusunga mawonekedwe ake oyambira (mkhalidwe) pansi pa mphamvu yakunja.

Kutayika kwa kukhazikika ndi chochitika chakuti chiwalo chachitsulo chimasintha mwadzidzidzi mawonekedwe oyambira a kukhazikika pamene kupanikizika kukukwera kufika pamlingo winawake, komwe kumatchedwa kusakhazikika. Ziwalo zina zopapatiza zokhala ndi makoma ochepa zimatha kusinthanso mwadzidzidzi mawonekedwe awo oyambira a kukhazikika ndikukhala osakhazikika. Chifukwa chake, zigawo zachitsulo izi ziyenera kukhala ndi mphamvu yosunga mawonekedwe awo oyambira a kukhazikika, kutanthauza kuti, zikhale ndi kukhazikika kokwanira kuti zitsimikizire kuti sizidzakhala zosakhazikika komanso zowonongeka pansi pa mikhalidwe yomwe yatchulidwa yogwiritsira ntchito.

Kusakhazikika kwa bala yokakamiza nthawi zambiri kumachitika mwadzidzidzi ndipo kumawononga kwambiri, kotero bala yokakamiza iyenera kukhala yokhazikika mokwanira.

Mwachidule, kuti zitsimikizo za zitsimikizo za zitsulo zigwire ntchito bwino komanso modalirika, zitsimikizo ziyenera kukhala ndi mphamvu zokwanira zonyamulira, kutanthauza kuti, zikhale ndi mphamvu zokwanira, kuuma ndi kukhazikika, zomwe ndi zofunikira zitatu zofunika kuti zitsimikizo za zitsimikizo zigwire ntchito bwino.

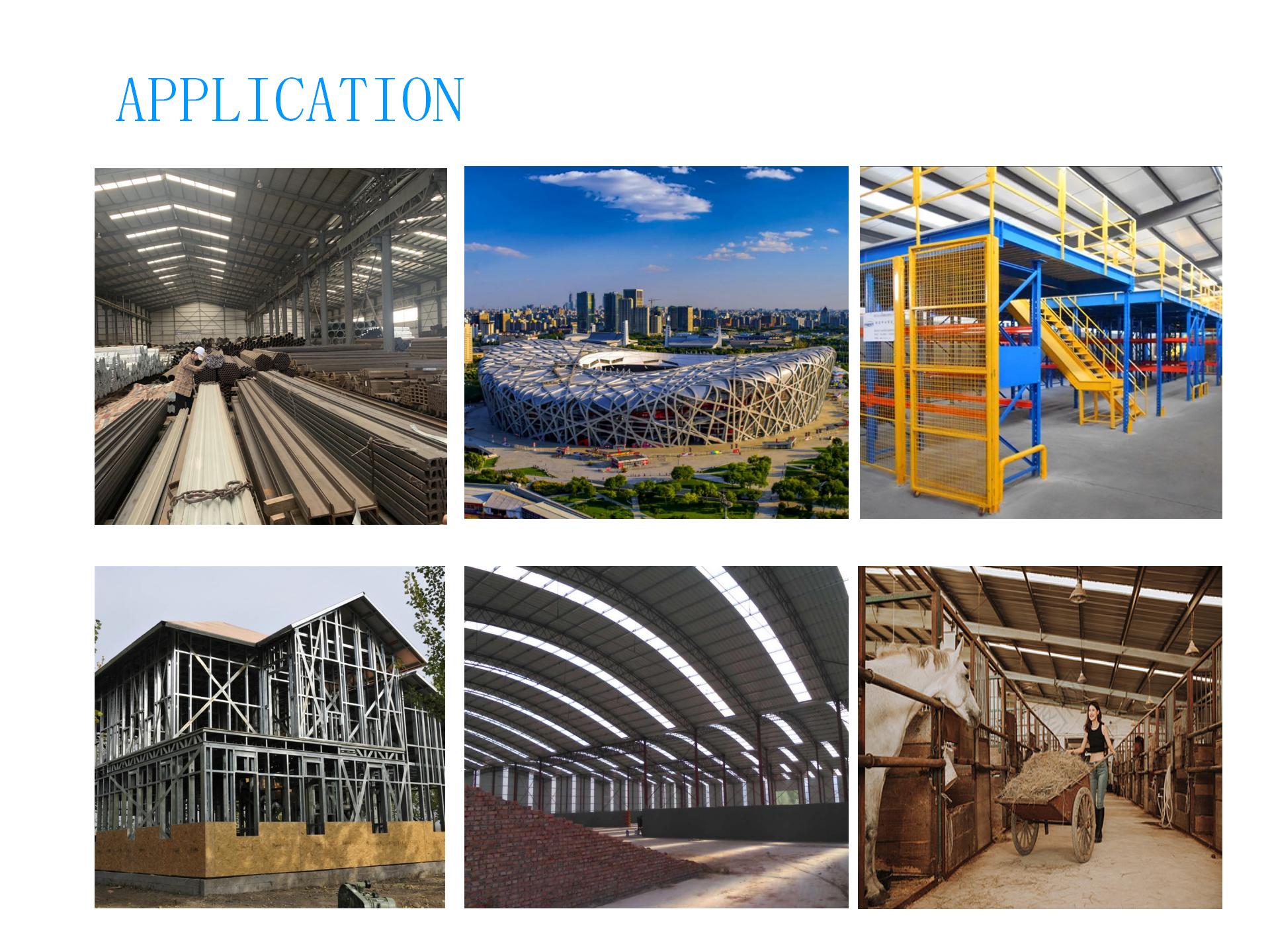

Kugwiritsa ntchito

Nyumba zamakampani:Fakitale Yopangira Zitsulonthawi zambiri amagwiritsidwa ntchito m'mafakitale kapena m'nyumba zosungiramo katundu. Fakitale Yopanga Zitsulo ndi gawo lokonzedwa kale, ndipo kukonza, kupanga, kunyamula ndi kukhazikitsa ndi kofulumira kwambiri. Kuphatikiza apo, ndi yopepuka kulemera ndipo ili ndi mphamvu yonyamula katundu komanso yolimba, zomwe zingatsimikizire chitetezo ndi kukhazikika kwa fakitale. Kuphatikiza apo, Fakitale Yopanga Zitsulo ikhoza kuswedwa ndikumangidwanso malinga ndi zosowa, ndi kusinthasintha kwamphamvu.

Nyumba zaulimi: Pa mbewu zosiyanasiyana ndi mbewu zaulimi, ili ndi ubwino wotumiza kuwala kwambiri, kugwiritsa ntchito bwino kutentha, kusunga mphamvu komanso kugwiritsa ntchito ndalama zochepa. Chogulitsachi chimagwiritsa ntchito kapangidwe kachitsulo kothandizira chimango ndi malo opanda mizati, kotero kuti mphamvu yonyamulira nyumba ya greenhouse ikhale yolimba, yokhazikika komanso yodalirika, ndipo izi zimagwiranso ntchito kwa ziweto zoweta.

Nyumba za anthu onse: Tsopano nyumba zambiri zazitali kapena malo ochitira masewera olimbitsa thupi amagwiritsa ntchito Chitsulo Chopanga Kapangidwe, chimatha kuteteza nyumbayo ku masoka achilengedwe ndi kuwonongeka kopangidwa ndi anthu, monga chivomerezi, moto ndi zina zotero; Kapangidwe kachitsulo sikophweka kuwononga, kukana kutentha kwambiri, kukana moto, kukonza kosavuta; Nyumba zachitsulo nthawi zambiri zimapangidwa ndi zipangizo zolimba kwambiri, ndipo chitsulocho sichifuna zida zokonzera, kotero chimasunga ndalama zambiri.

Malo Okhala: Makhalidwe a kapangidwe ka chitsulo ali ndi mikhalidwe yopangitsa nyumbayo kukhala yopepuka komanso yowonekera bwino, zomwe zimapangitsa kuti pakhale kutsanzira malo akuluakulu komanso luso lopanga zinthu zovuta kwambiri. Ndi yotsika mtengo komanso yosagwiritsa ntchito mphamvu zambiri.

Pulatifomu ya Chipangizo: Zipangizo zopangira za nsanja ya Steel Structure Warehouse zili ndi kusintha kwabwino kwa pulasitiki komanso kusinthasintha, ndipo zimatha kusintha kwambiri, kotero zimatha kupirira mphamvu yoyendetsera bwino. Zimathanso kufupikitsa nthawi yomanga ndikusunga nthawi ndi mphamvu ya anthu. Mulingo wodziyimira pawokha wa uinjiniya wa kapangidwe ka zitsulo ndi wokwera, womwe ungathe kupanga ndi kupanga mwadongosolo, kukonza magwiridwe antchito, kuchepetsa zovuta pakupanga uinjiniya, ndikukwaniritsa mawonekedwe a ntchito yothamanga kwambiri komanso kuteteza chilengedwe pakukula kwa anthu.

NTCHITO

Nyumba ya Empire State ndi nyumba yokongola kwambiri yotchuka yomwe ili pa 350 Fifth Avenue, pakati pa West 33rd Street ndi West 34th Street ku Manhattan, New York City, New York, United States. Ndi nyumba yomangidwa mu Art Deco.Kapangidwe ka ZitsuloInayamba mu 1930 ndipo inamalizidwa mu 1931. Inamalizidwa ndipo ntchito yomanga inatenga masiku 410 okha, zomwe ndi mbiri yachangu kwambiri padziko lonse lapansi.

Kulongedza ndi Kutumiza

Kulongedza: Malinga ndi zomwe mukufuna kapena zomwe zikugwirizana ndi zosowa zanu.

Manyamulidwe:

Sankhani njira yoyenera yoyendera: Kutengera kuchuluka ndi kulemera kwa chitsulocho, sankhani njira yoyenera yoyendera, monga magalimoto oyenda pansi, makontena, kapena zombo. Ganizirani zinthu monga mtunda, nthawi, mtengo, ndi zofunikira zilizonse zokhudzana ndi mayendedwe.

Gwiritsani ntchito zida zoyenera zonyamulira: Kukweza ndi kutsitsaNyumba yosungiramo katundu yachitsuloGwiritsani ntchito zida zoyenera zonyamulira monga ma crane, ma forklift, kapena ma loaders. Onetsetsani kuti zida zomwe zagwiritsidwa ntchito zili ndi mphamvu zokwanira zonyamula kulemera kwa milu ya mapepala mosamala.

Mangani katundu: Mangani bwino katundu wopakidwa pa galimoto yonyamula katundu pogwiritsa ntchito zomangira, zomangira, kapena njira zina zoyenera kuti mupewe kusuntha, kutsetsereka, kapena kugwa panthawi yoyenda.

MPAMVU YA KAMPANI

Yopangidwa ku China, ntchito yapamwamba kwambiri, yapamwamba kwambiri, yotchuka padziko lonse lapansi

1. Zotsatira za kukula: Kampani yathu ili ndi unyolo waukulu wogulira zinthu ndi fakitale yayikulu yachitsulo, zomwe zimapangitsa kuti zinthu ziyende bwino komanso kugula zinthu, komanso kukhala kampani yachitsulo yomwe imagwirizanitsa kupanga ndi ntchito.

2. Kusiyanasiyana kwa zinthu: Kusiyanasiyana kwa zinthu, chitsulo chilichonse chomwe mukufuna chingagulidwe kwa ife, makamaka chogwiritsidwa ntchito mu zomangamanga zachitsulo, njanji zachitsulo, milu ya pepala lachitsulo, mabulaketi a photovoltaic, chitsulo cha channel, ma coil achitsulo cha silicon ndi zinthu zina, zomwe zimapangitsa kuti chikhale chosinthasintha. Sankhani mtundu wa chinthu chomwe mukufuna kuti chikwaniritse zosowa zosiyanasiyana.

3. Kupereka zinthu mokhazikika: Kukhala ndi mzere wokhazikika wopanga zinthu komanso unyolo wogulira zinthu kungapereke zinthu zodalirika. Izi ndizofunikira kwambiri kwa ogula omwe amafunikira zitsulo zambiri.

4. Mphamvu ya mtundu: Amakhala ndi mphamvu yayikulu ya mtundu komanso msika waukulu

5. Utumiki: Kampani yayikulu yachitsulo yomwe imagwirizanitsa kusintha, mayendedwe ndi kupanga

6. Mpikisano pamitengo: mtengo wovomerezeka

* Tumizani imelo kwa[email protected]kuti mupeze mtengo wa mapulojekiti anu

KUPITA KWA MAKASITOMALA